LIST OF WAFER

FABRICATION EQUIPMENT

The following companies participated in the

construction work under the supervision of VARIOPLAN-Switzerland:

-

Meissner und Wurst GmbH : Heating,

Cooling, Airconditioning Units.

-

Siemens : Electrical Installation

-

Hager Elsasser GmbH : DI Water and

Neutralization Systems.

-

Laflow GmbH : Laminar Flow Hoods and

Wet Benches

-

Ritterwand : Ceiling and Walls

-

P.K. Müller GmbH : Gas Distribution

Systems

-

Arthur Haller : Antistatic, Conductive Floors

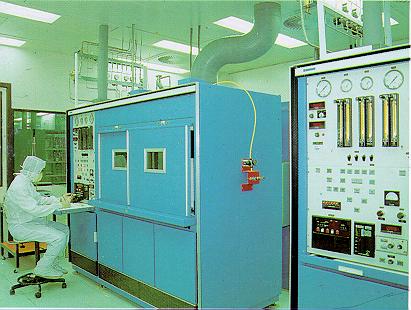

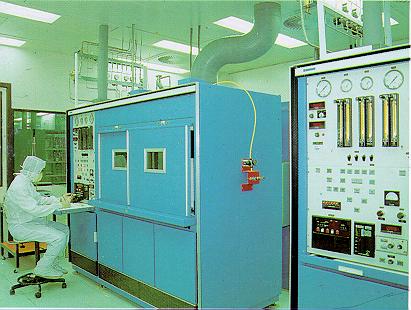

DIFFUSION AREA

-

Main Area

-

THERMCO Four-Stack Diffusion Furnace Systems :

-

Nine (9), Model 4104 Four-Stack Diffusion Furnaces

-

Nine (9), Model 4100 Load Stations

-

Twenty-Four (24), Model A-2 Boat Loaders

-

Nine (9), Model 4100 Gas Source Cabinets with Eight

(8) Type Gas Systems

-

Thirty-Six (36), Model 8016 Programmers

-

Four (4), Wet Benches (LAFLOW)

-

Three (3), Rinser/Dryers (HEREAUS)

-

One (1), Nanospec/AFT Computerized Film Thickness

Measurement System NANOMETRICS INC.)

-

One(1), Model M-700 Four Point Probe System (MAGNETRON

INS.)

-

One (1), Inspection Microscope (NIKON)

-

B/L Preparation Room

-

One (1), Model 703 Scrubber (MTI)

-

One (1), Model EC101D Series Photoresist Spinner

(HEADWAY RESEARCH INC.)

-

One (1), Model 3490 M-1 Oven (LAB-LINE INSTRUMENTS

INC.)

-

Chemical Room For Cleaning Quartzware And Metal

Pieces

-

Three (3), Wet Benches (FELL GROUP)

EPI AREA

-

Two (2), AMV-1200 Dual Vertical Epitaxial Reactor

Systems (APPLIED MATERIALS) together with 50 KW RF GENERATORS (WESTINGHOUSE)

and ES-500 Effluent Gas Scrubbers (APPLIED MATERIALS)

-

One (1), Model 1430 Ratio Recording Infrared Spectrophotometer

(PERKIN-ELMER)

-

One (1), Model M-700 Four Point Probe System (MAGNE-

TRON INSTRUMENTS)

-

One (1), Model 80 Series Digital Infrared Thermometer

(MICRON INSTRUMENTS COMPANY INC.)

-

TWO (2), Model PM 80 Wafer Spin Cleaners (HEADWAY

RESEARCH INC.)

-

One (1), Wet-Bench (LAFLOW)

-

One (1), Rinser/Dryer (HEREAUS)

-

One (1), Stroboscope (COLE-PARMER)

-

One (1), Inspection Microscope (NIKON)

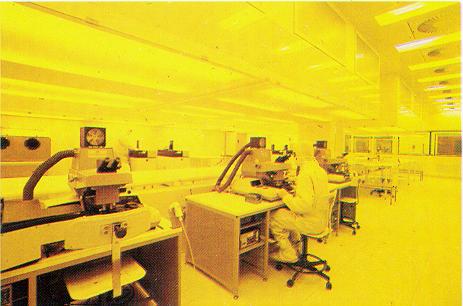

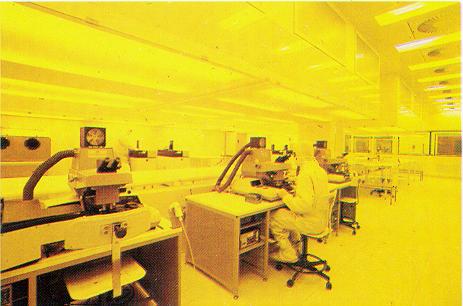

LITHOGRAPY AREA

-

Yellow Room

-

Three (3), Model 702 Photoresist Coater Systems

(MTI)

-

Three (3), Model 703 Photoresist Developer Systems

(MTI)

-

Two (2), Model CA-800 Cobilt Manual Mask Aligners

(APPLIED MATERIALS)

-

One (1), Model CA-800 Cobilt Mask Aligner with

AL-550 Automatic Wafer Loading Option (APPLIED MATERIALS)

-

Two (2), Model 3490 M-1 Ovens (LAB-LINE INS.INC.)

-

Two (2), Inspection Microscopes

(NIKON)

-

Red Room

-

One (1), Model 142 Contact Printer (TAMARACK SCIENTIFIC

CO.INC.)

-

One (1), Photomask Process Station (DEXON)

-

One (1), Rinser/Dryer (HEREAUS)

-

Two (2), Mask Plate Inspection Microscopes (NIKON)

ETCH AREA

-

Five (5), Wet-Benches (LAFLOW)

-

Four (4), Rinser/Dryers (HEREAUS)

-

Two (2), Model 3005-1813 SCA Automatic Plasma Systems

with PM 119 RF Generators (IPC-BRANSON)

-

One (1), Model 2015 Sectioner (PHILTEC)

-

One (1), Model 3490 M-1 Oven (LAB-LINE INS.INC.)

-

Two (2), Inspection Microscopes (NIKON)

THIN FILM AND PASSIVATION

AREA

-

One (1), Model 3119 R&D Single Crucible-10

KW e-GUN Source System (VARIAN)

-

Two (2), Model 3119 R&D 5KVA Filament Source

Coater Systems (VARIAN)

-

One (1), Wet-Bench (LAFLOW)

-

One (1), Rinser/Dryer (HEREAUS)

-

One (1), Model 216 CVD Reactor (G.S TEMPRESS B.V.)

BACK-LAP ROOM

-

One (1), Model SNG-32BAW 2088 Back Lapping Machine

(SPEEDFAM CORP.)

-

One (1), Wafer Mount/Dismount Station for Back-Lap

Process. (SPEEDFAM CORP.)